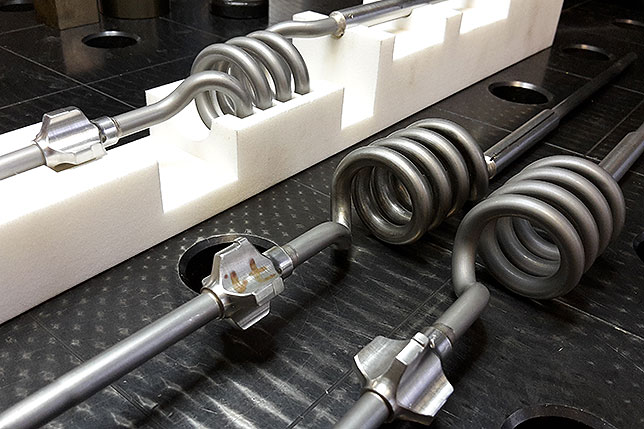

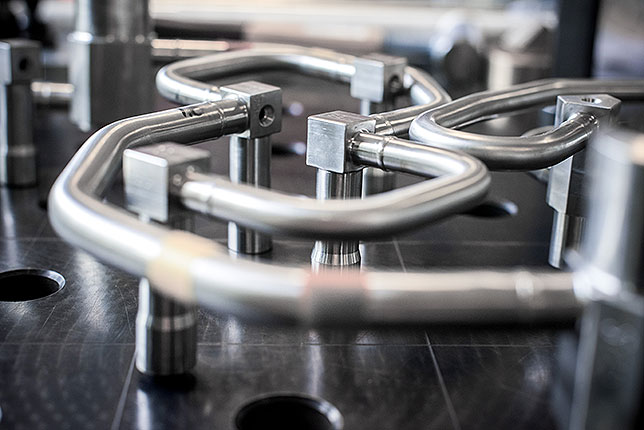

Assemblies

Components from high-grade material

Widespread specialisation in the turning, milling, bending & welding technology at TUBE-TEC enables manufacturing of singles & fabrication of complete assemblies, here are just a few:

- Combustion chamber pipework/piping systems with welded / brazed fittings

- Pump connections incl. pipework/piping systems

- Heating kits

- Sensitive bent parts combined with diverse configurations of turned & milled parts

- Oil & gas pipework/piping systems

- Highly demanding & sensitive fluid pipework

- as well as every form & type of fittings incl. pipework/piping systems

Specialised in the physical processing of `difficult´ materials such as Inconel, austenitic steels, Duplex steels, Hastelloy and high temperature-resistant Nickel alloys, TUBE-TEC is the forerunner when it comes to international know-how.

Mechanical workshops with state-of-the-art CNC processing centers from names such as DMG MORI, in which the product is `intimately´ measured and comprehensively tested in the course of fabrication, and CT scanning / X-ray possibilities for complete subassemblies on our own premises.

We can guarantee highly-precise & rapid manufacturing speeds, even when talking about large-volume production figures.

ADVANTAGES

- Most modern CNC lathes & milling machines

- Orbital welding guns with the absolute latest welding technology

- Digital X-raying of complete subassemblies

- Physical processing of `difficult´ materials such as austenitic steels, Duplex steels, Inconel materials, Hastelloy, and high temperature-resistant Nickel alloys